Ultimate Checklist for Choosing the Best Proportional Valves for Your Applications

In today's competitive landscape, the selection of the right Proportional Valves is crucial for optimizing performance and efficiency in various applications, from industrial automation to mobile machinery.

Recent industry reports indicate that the global market for proportional valves is projected to grow significantly, reaching approximately $3.5 billion by 2025, driven by advancements in technology and increasing demand for precision control in hydraulic systems.

As industries strive for greater operational efficiency and sustainability, understanding the key factors influencing the selection of Proportional Valves becomes paramount.

This ultimate checklist will guide you through essential considerations, ensuring that you make informed decisions that align with your specific application needs while capitalizing on the latest technical advancements.

Trends Shaping the Proportional Valve Market by 2025

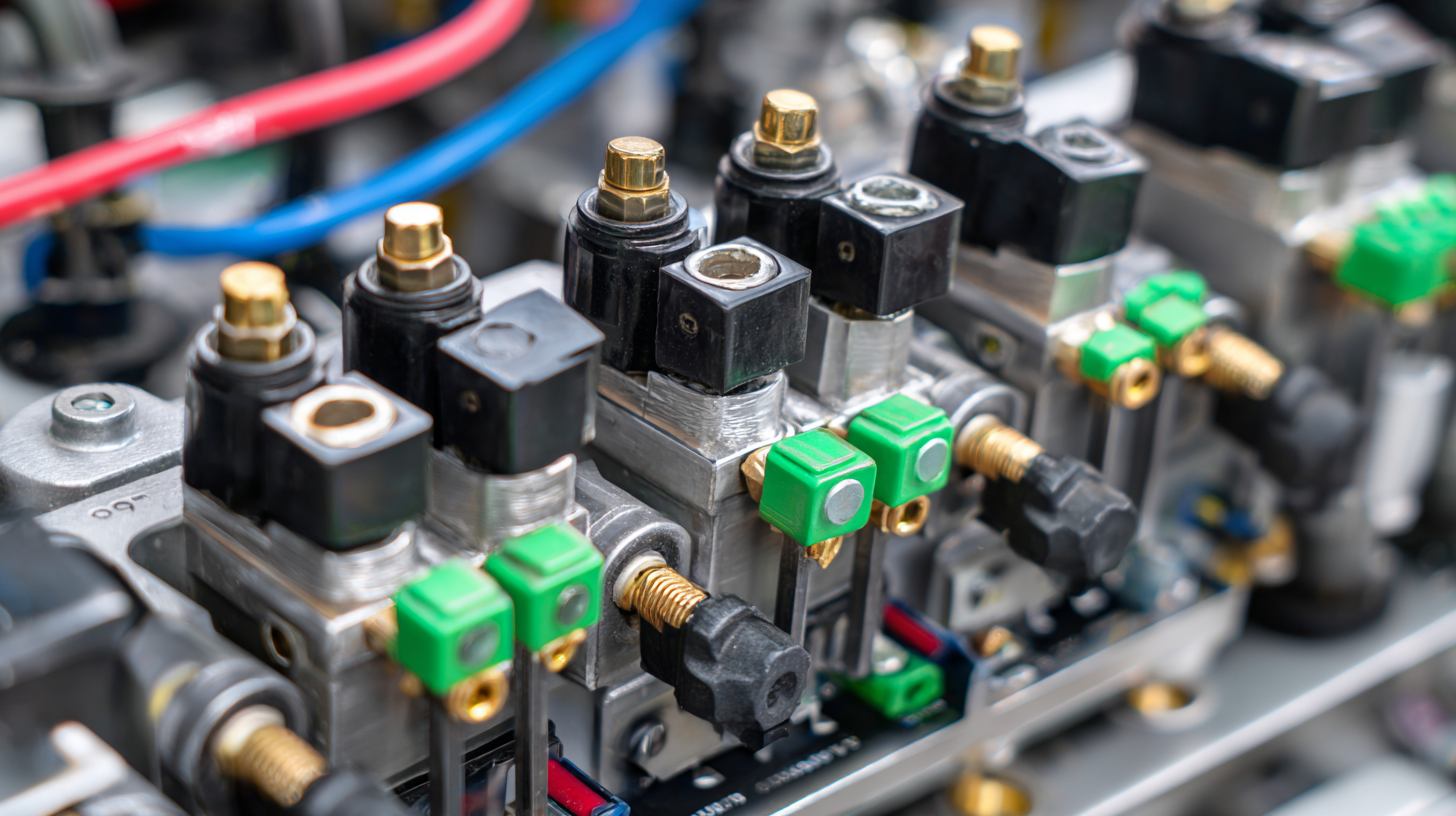

As we look ahead to 2025, several key trends are expected to shape the proportional valve market, driving innovation and efficiency across various industries. One significant trend is the increasing demand for automation in manufacturing processes. With the rise of Industry 4.0, companies are prioritizing smart technologies that require advanced proportional valves for precise control of fluid movement. This shift not only improves operational efficiency but also enhances product quality, making proportional valves an essential component in automated systems.

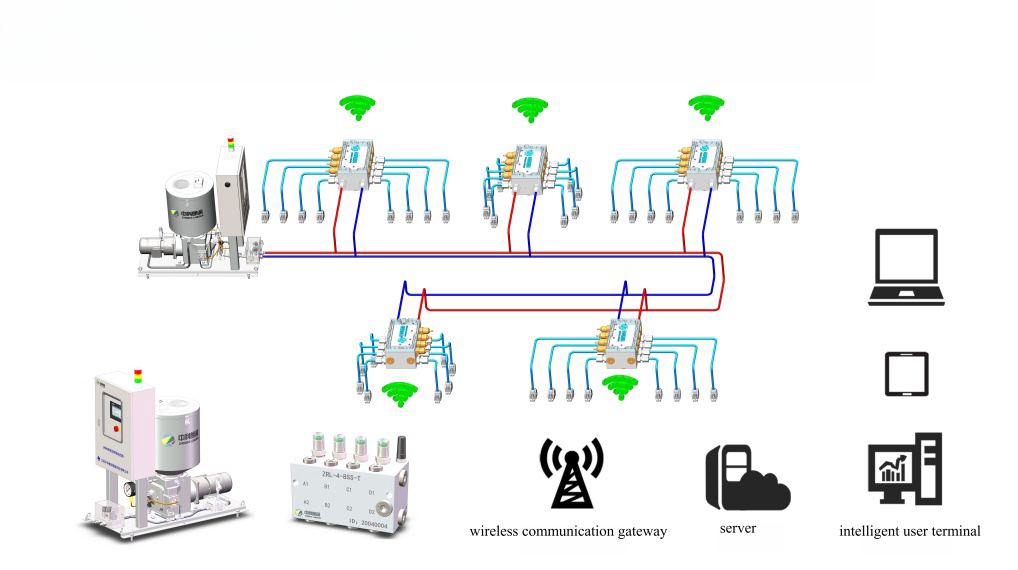

Another trend is the growing emphasis on energy efficiency and sustainability. Users are more conscious of their environmental impact, prompting manufacturers to develop proportional valves that consume less energy while maintaining high performance. The integration of IoT technology is also playing a pivotal role, as it allows for real-time monitoring and data analysis, further optimizing energy use and predictive maintenance. As the market evolves, these trends will drive the development of more sophisticated proportional valve solutions that cater to the changing needs of industries, ensuring both operational excellence and sustainability.

Key Factors to Consider When Selecting Proportional Valves for Specific Applications

When selecting proportional valves for specific applications, it's crucial to consider several key factors that can significantly impact performance and efficiency. One important aspect is the valve's responsiveness, which is often measured in terms of switching time and frequency. According to a report by Research and Markets, the global proportional valve market is expected to grow at a CAGR of 5.3% from 2021 to 2028. This growth underscores the increasing demand for high-performance valves that can handle rapid adjustments in various industrial applications.

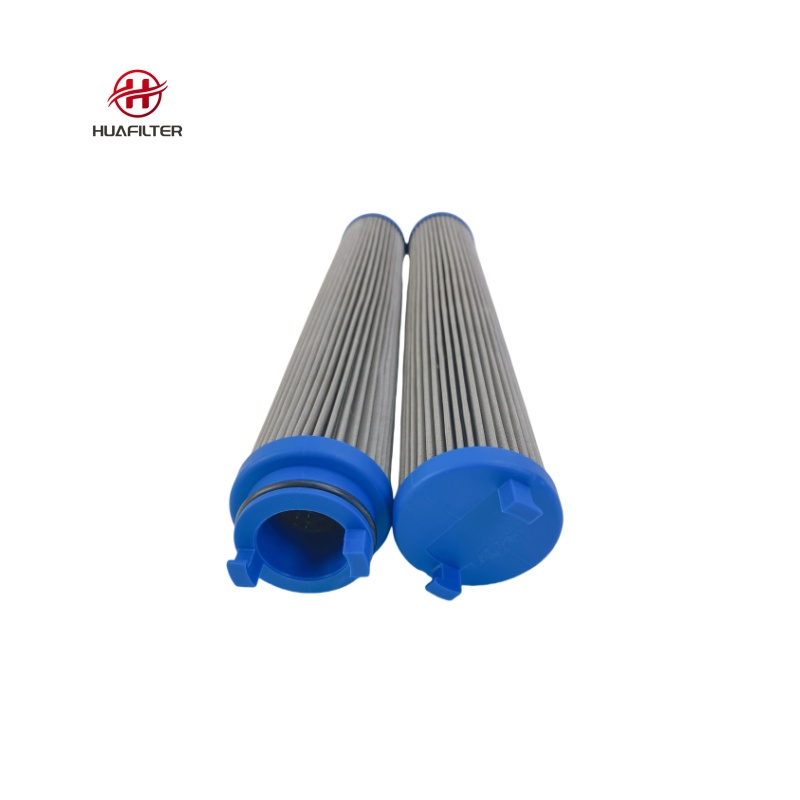

Another critical factor is the compatibility with the fluid medium being controlled. For instance, hydraulic systems may require valves that can operate effectively under high pressures and temperatures. The International Journal ofFluid Mechanics Research highlights that choosing the right material for seals and body construction is vital to avoid premature failure due to corrosive or abrasive fluids. Additionally, valve size and flow characteristics are essential in ensuring that the selected valve can meet the system's specifications while optimizing energy consumption and minimizing waste.

Proportional Valves Performance Comparison

Analyzing the Role of Digital Technologies in Enhancing Valve Performance

In the rapidly evolving world of industrial automation, digital technologies have become indispensable in enhancing the performance of proportional valves. These sophisticated devices, which regulate fluid flow and pressure, are now being integrated with advanced automation systems, enabling users to achieve a higher level of precision in their applications. By employing sensors and IoT capabilities, users can monitor valve performance in real-time, facilitating timely adjustments and predictive maintenance that ultimately reduce downtime and operational costs.

Furthermore, digital technologies enable the seamless integration of proportional valves into broader process control systems. The use of data analytics allows for the optimization of valve operation, providing insights that drive efficiency and improve overall system performance. Techniques such as machine learning can predict valve behavior under varying conditions, allowing operators to fine-tune settings for specific applications and achieve optimal results.

As industries continue to embrace Industry 4.0, the role of digital technologies in proportional valve performance will only become more pronounced, ushering in a new era of automation and control.

Tips for Evaluating the Efficiency and Quality of Proportional Valves

When evaluating the efficiency and quality of proportional valves for your specific applications, several key factors should be meticulously considered to ensure optimal performance. First, it's essential to analyze the specifications of the proportional valves in relation to the operational requirements. For instance, data from recent studies indicate that the performance of proportional solenoid current can significantly impact key variables like clutch pressure, speed, and torque in automatic transmission systems. These interrelated parameters underscore the importance of precise control mechanisms in achieving seamless operational efficiency.

Moreover, the material composition and design of the valves also play a crucial role in their overall effectiveness. The latest advancements in materials science highlight that

lightweight and high-strength alloys can enhance the durability and responsiveness of mechanical components. Notably, a review on advanced lightweight materials reveals that implementing these innovations in automotive applications can lead to not only improved performance but also a reduction in emissions, which aligns with the industry’s ongoing pursuit of

sustainability.

Lastly, quality control measures must be integrated into the selection process. As demonstrated in pilot studies of extensive green roofs, analyzing the performance metrics under varying conditions, such as natural rainfall events, can provide valuable insights into the longevity and reliability of proportional valves. Thus, comprehensive assessments based on scientific evaluations can lead to informed decisions that elevate the effectiveness of your applications significantly.

Cost-Benefit Analysis: Investing in Proportional Valves for Long-term Gains

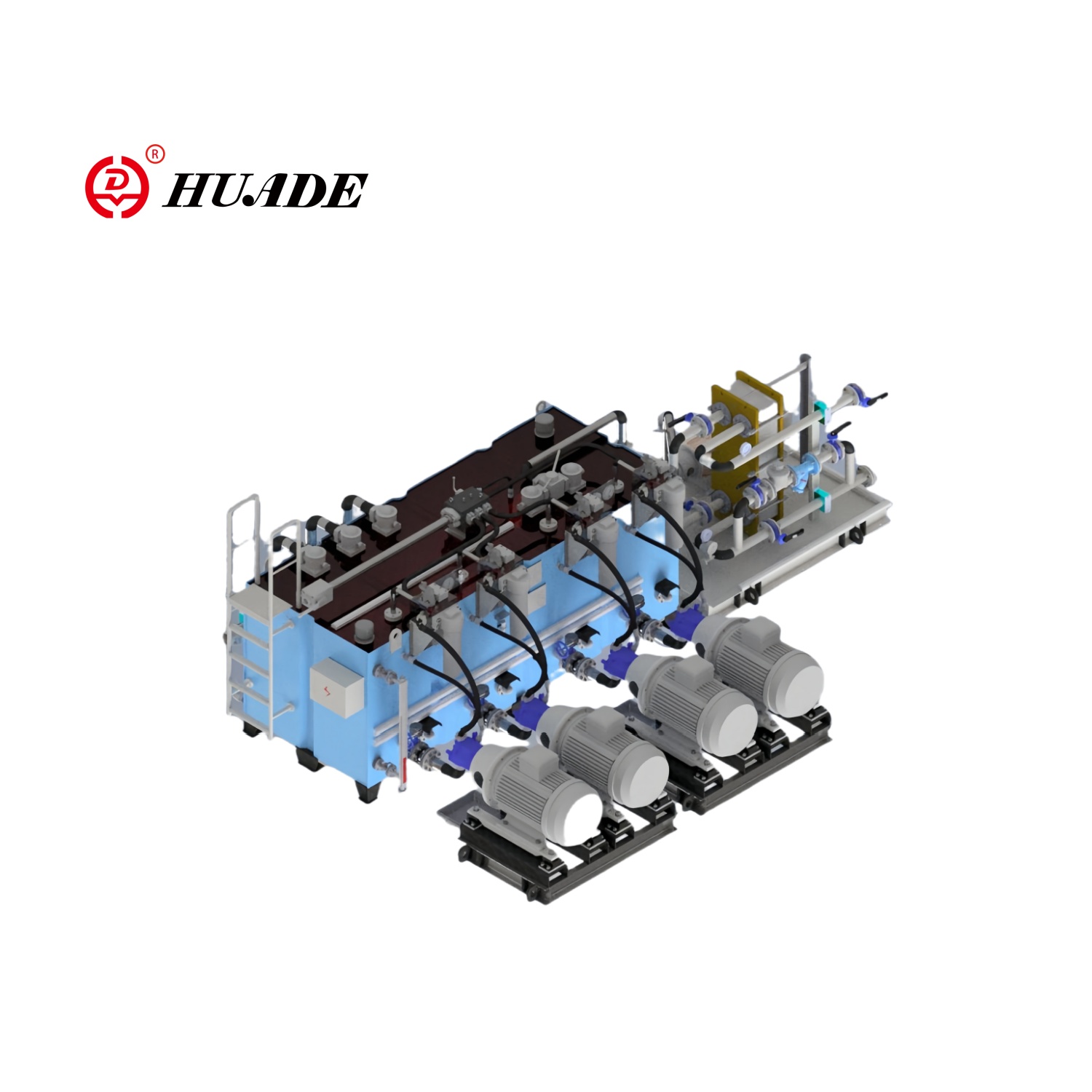

When considering investments in proportional valves, a thorough cost-benefit analysis is essential for maximizing long-term gains. Proportional valves are not merely components; they play a pivotal role in enhancing system efficiency, accuracy, and responsiveness across various applications. By regulating fluid flow and pressure with precision, these valves can significantly reduce energy consumption and operational costs over time. This leads to improved productivity and can even extend the lifespan of machinery by minimizing wear and tear, making the initial investment more justifiable.

However, the decision-making process shouldn't solely hinge on upfront costs. It's vital to evaluate the total cost of ownership, which includes maintenance, energy savings, and potential downtimes. Investing in high-quality proportional valves designed for specific operations can lead to substantial reductions in maintenance frequency and costs, ultimately resulting in higher returns on investment. Additionally, consider the adaptability of these valves in your systems; the more versatile the valve, the longer it can serve various purposes, providing further savings as your operational needs evolve.